ARMORED SUBMERSIBLE Power CABLE

페이지 정보

본문

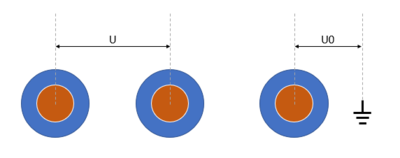

In such an instance, the protective layer can be a cushion layer that can be an extruded cushion layer that features XLPE and optionally a number of extra supplies (e.g., PP, talc, carbon black, and so on.). In such an instance, the metallic shield layer could serve as a ground plane. In some embodiments, an insulation layer and insulation shield layer could be co-extruded via pressure extrusion and cured utilizing appropriate cure methods with substantially comparable cure charges. In some embodiments, a mixture of extruded and taped layers could also be used to type the barrier layer. In other embodiments, an insulation shield layer could also be tandem extruded with an insulation layer. In some embodiments, an insulation shield may be strippable (e.g., to allow for termination and electrical testing of the cable). For example, insulation and shield could also be strippable as a unit, for example, the place considerably cross-linked at an interface between the insulation and the shield. For instance, a metallic shield layer could also be formed from quite a lot of metallic materials including, but not limited to: copper, aluminum, lead, and alloys thereof. Additionally, low cost fillers or additives could be compounded right into a cushion layer materials to further reduce material value.

As mentioned, an individual cushion layer may encompass a person considered one of a metallic shield where such a cushion layer could also be considerably circular in form, considerably pie shaped, or another form. For instance, a lead (Pb) based mostly barrier layer can be a metallic shield layer that can also function a floor airplane. For example, carbon black can make a crosslinked polyethylene cushion layer extra opaque and of a shade that tends to be consistent. For example, an insulation shield layer can optionally be a semi-conductive layer applied over an insulation layer to reduce electrical stresses in a cable. As mentioned, the shape of a cushion layer could also be substantially circular or of one other shape such as, for instance, considerably pie shaped the place it might surround a substantially pie shaped metallic barrier layer (e.g., a lead (Pb) barrier layer). For instance, a barrier layer is usually a layer exterior to a shield (e.g., an insulation shield layer) which will purpose to offer extra safety from corrosive downhole gases and fluids. For example, a cable may carry energy, at occasions, for example, with amperage of up to about 200 A or more.

In the example of FIG. 6, the cable 610 with the circular cross-sectional form has an area of unity and the cable 630 with the oblong cross-sectional shape has area of about 0.82. As to perimeter, where the cable 610 has a perimeter of unity, the cable 630 has a perimeter of about 1.05. Thus, the cable 630 has a smaller volume and a larger surface space when compared to the cable 610. A smaller volume can provide for a smaller mass and, for example, less tensile stress on a cable that could be deployed a distance in a downhole setting (e.g., as a consequence of mass of the cable itself). For example, the facility cable 701 can include armor where the cushion layer 760 helps to protect one or more metallic shields from deformation resulting from power imparted during an armoring course of and the facility cable 702 can embrace armor the place the cushion layers 760 and/or the cushion layer 762 assist to protect one or more metallic shields from deformation due to pressure imparted during an armoring process. The information of the plot 1400 confirms that immersing the extruded XLPE film in water for roughly 12 hours at approximately eighty degrees C. is environment friendly for a completely curing process.

If you have any questions concerning where and how you can use low voltage armored power cable, you could contact us at our own web site.

- 이전글텔1레@prmecoin 카드로코인구매하는법 25.05.30

- 다음글Prosecutor Questions Statements Sheriff Made After Taking pictures Prepare for a career in the industrial real property trade, studying essential skills comparable to how to manage, worth and develop properties. At present, in accordance with the Guardian 25.05.30

댓글목록

등록된 댓글이 없습니다.